Immersion Cooling

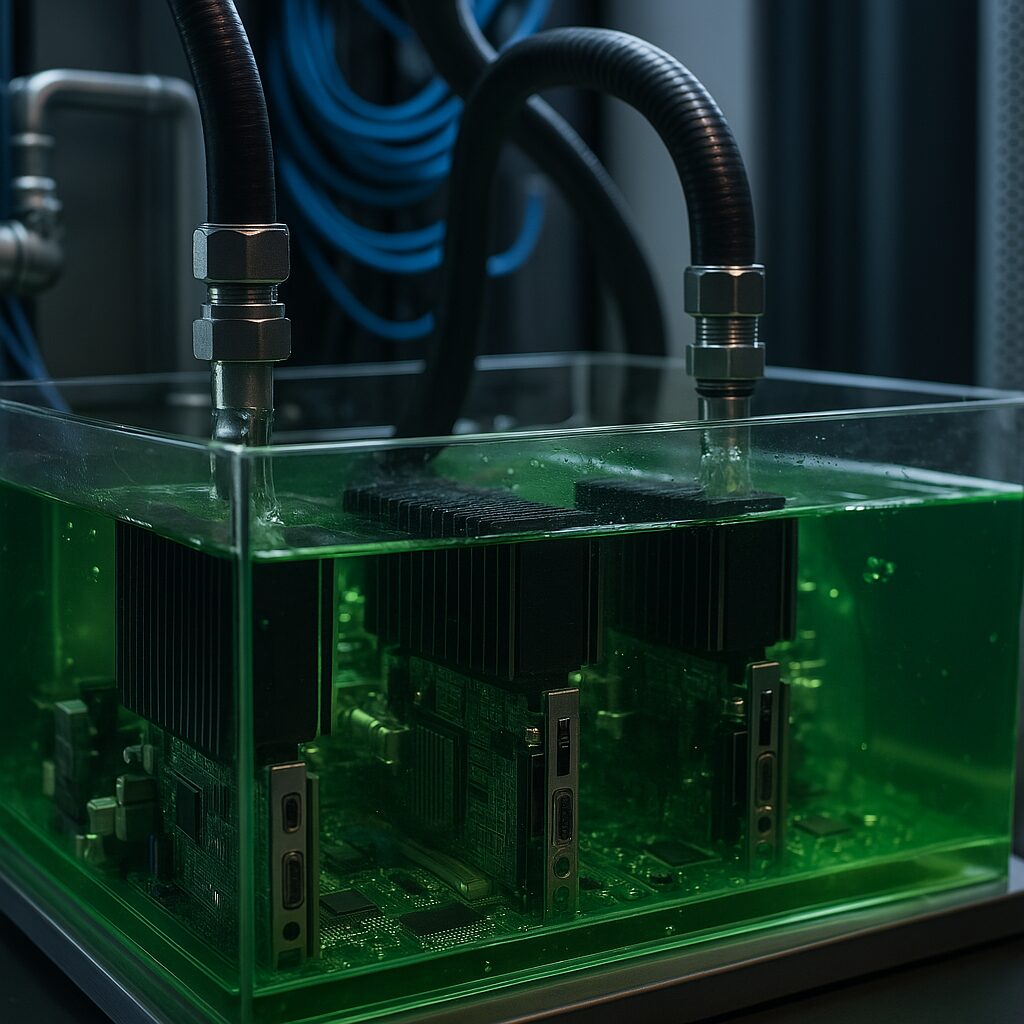

Immersion cooling is an advanced thermal management method that submerges computer hardware directly into a specially engineered, non-conductive liquid to keep it cool. Unlike traditional cooling systems that rely on air or liquid flowing through closed loops in pipes and heat sinks, immersion cooling works by allowing heat to transfer directly from electronic components into a surrounding fluid. It’s a remarkable shift in how we think about thermal regulation in computing, and it’s gaining momentum as we push the limits of performance in high-density environments like data centers and AI supercomputing labs.

At the core of immersion cooling is the use of dielectric fluids, liquids that do not conduct electricity. This is critical because it ensures that when motherboards, GPUs, and other circuitry are fully submerged, there's no risk of short-circuiting or electrical damage. These fluids are formulated to have high thermal conductivity and chemical stability, allowing them to absorb and transfer heat away from components with exceptional efficiency. They're also designed to be non-toxic and have a long lifecycle, which is important when designing sustainable and reliable infrastructure.

There are two primary categories of immersion cooling: single-phase and two-phase systems. In single-phase immersion cooling, the coolant remains in liquid form throughout its entire cycle. It flows over the components, picks up the heat, and is then pumped through a heat exchanger where it releases that heat, into water or air, before returning to the hardware to start the cycle over again. This method is relatively simple and easier to implement, with lower maintenance requirements.

Two-phase immersion cooling takes advantage of the phase change process. The fluid boils upon contacting hot surfaces like CPUs or GPUs, turning into vapor. The latent heat of vaporization removes heat as it transitions from liquid to vapor, absorbing large amounts of heat efficiently. The vapor then rises to condense on a cooler surface, often a condenser coil, where it turns back into a liquid and drips down to repeat the process. This type of system is incredibly effective for managing high thermal loads but involves more complex design and regulation to control vapor dynamics and condensation.

The demand for computing power is skyrocketing, especially in fields like artificial intelligence, machine learning, scientific simulations, and cryptocurrency mining. These applications generate enormous amounts of heat, and traditional air-based cooling methods are becoming less capable of keeping up, especially when efficiency, reliability, and sustainability are top priorities. This puts immersion cooling in very high demand.

By eliminating the need for internal fans and complex airflow management, immersion cooling can reduce overall power consumption in a data center, sometimes by as much as 30–40%. The energy savings primarily come from the drastically reduced need for air conditioning, which is one of the largest energy drains in modern server environments aside from the computational power needs. For facilities chasing aggressive carbon neutrality goals, this is a breakthrough worth developing and implementing.

Because immersion cooling reduces thermal stress and maintains components at a more stable temperature, it can extend the lifespan of the hardware and decrease failure rates. There’s less dust, fewer vibrations, and a quieter operating environment, all of which contribute to more predictable and manageable systems. With the need for less physical space devoted to airflow channels and cooling infrastructure, server racks can be packed more densely, optimizing footprint.

From a sustainability angle, this approach holds even more promise. Some dielectric fluids are now recyclable and biodegradable, and ongoing research focuses on fluids with minimal environmental impact. Combined with renewable-powered data centers, immersion cooling becomes an important tool in building climate-conscious computing ecosystems.

Immersion cooling does come with some trade-offs. The upfront cost of retrofitting existing data centers or investing in immersion-ready infrastructure can be high. There are also logistical challenges such as handling large volumes of fluid, maintenance protocols, and training staff unfamiliar with the technology. Regulatory guidance is still catching up, which creates uncertainty in some markets.

It is still hard to overstate the potential of immersion cooling. As more organizations seek efficient ways to scale computational capability while reducing energy use and environmental impact, immersion cooling is becoming less of a novelty and more of a necessity. It symbolizes a growing willingness to rethink fundamental design principles, to question legacy norms and embrace solutions that blur the lines between engineering, sustainability, and systems thinking.

Single-phase Immersion Cooling

Single-phase immersion cooling is a fascinating blend of simplicity and engineering precision, offering a powerful and energy-efficient way to cool modern computer systems without the need for fans, heatsinks, or traditional air-based climate control. At its core, this system involves placing entire electronic assemblies, like servers or other heat-generating components, into a bath of thermally conductive, electrically insulating liquid. Unlike traditional air cooling, which relies on moving heat from components to the surrounding air and then out of a chassis or building, single-phase immersion cooling eliminates the inefficiencies of transferring heat across multiple materials and interfaces.

The defining feature of a single-phase system is that the cooling liquid does not undergo a phase change during operation, remaining a liquid from start to finish. Heat is transferred directly from the electronics into the surrounding fluid, which absorbs it and carries it away from the sensitive equipment. The now-warmed liquid is typically pumped through a heat exchanger, often integrated into the immersion tank or connected by fluid lines, where it releases the captured heat into a secondary medium like chilled water or air. Once cooled, the liquid is cycled back into the tank to repeat the process continuously.

Because the electronic components are submerged in a uniform medium with excellent thermal conductivity, heat dissipation is much more even and predictable compared to relying on discrete cooling paths like heatsinks or air ducts. There are no hotspots caused by blocked airflow or insufficient thermal paste; the entire component surface is in contact with the coolant at all times. This uniformity enables higher thermal stability and reduces the chances of localized overheating that could degrade performance or shorten hardware lifespan.

Another important point is the nature of the dielectric liquid itself. These fluids are specifically engineered for immersion use. They are typically fully inert, non-toxic, and non-flammable, and they won’t corrode sensitive electronic components. Many are synthetic hydrocarbons, fluorocarbons, or silicone-based compounds designed for long-term use without significant degradation. Some vendors are now focusing on sustainability by developing biodegradable or recyclable variants, which is an exciting development for environmentally conscious deployments.

Compared to two-phase cooling systems, which involve complex vaporization and condensation cycles, single-phase systems are easier to manage and more forgiving in day-to-day operation. There’s no need to precisely manage pressure or condensation surfaces, and maintenance crews are less likely to encounter complications with vapor leaks or uneven fluid behavior. This simplicity is particularly appealing for organizations looking to pilot immersion cooling without fully overhauling their infrastructure or retraining staff on more advanced thermofluidics.

From an operational standpoint, the tank housing the servers in single-phase systems is relatively straightforward. It’s usually constructed from corrosion-resistant materials and designed for easy fluid flow around components. The servers themselves are often specially configured to fit into the immersion environment: heatsinks and fans are removed, and materials like gaskets or solder are selected for compatibility with the coolant. Some systems even allow hot-swapping of components while submerged, although that remains more common in specialized setups.

In terms of scalability, single-phase immersion cooling can be deployed in small-scale edge computing environments all the way up to hyperscale data centers. Many startups and enterprises are experimenting with micro data center units, compact, self-contained immersion tanks that can be installed in office buildings or remote locations with limited access to cooling infrastructure. Meanwhile, large cloud service providers are piloting immersion cooling at scale to reduce power consumption, minimize environmental impact, and accommodate increasingly powerful processors that push thermal boundaries.

The energy efficiency gains here are significant. Because the coolant’s thermal properties are far superior to those of air, it takes much less energy to keep components within safe operating temperatures. By eliminating fans and reducing reliance on facility-wide HVAC systems, single-phase immersion setups can lead to Power Usage Effectiveness scores approaching 1.05, compared to the 1.5 or higher often seen in traditional air-cooled data centers. That translates to massive energy savings and lower operational costs over time.

Still, it’s not a one-size-fits-all solution. Switching to immersion cooling requires thoughtful consideration of existing infrastructure, compatibility with IT equipment, and investment in new monitoring and maintenance protocols. The business case often hinges on factors like local electricity costs, climate conditions, density of computing resources, and sustainability goals. Yet as hardware demands grow and environmental pressures mount, single-phase immersion cooling is increasingly being viewed as a practical and progressive option, not just for niche use cases, but for mainstream deployment.

Two-phase Immersion Cooling

Two-phase immersion cooling is a fascinating leap in thermal management that harnesses the raw physics of phase change to dissipate heat far more efficiently than traditional air or even liquid-cooled systems. It’s like watching an elegant science experiment happening inside a server tank, where boiling and condensation are not only intentional, but instrumental in keeping the hottest computing workloads cool, stable, and efficient.

At its core, two-phase immersion cooling submerges high-performance computing components, like CPUs, GPUs, and memory, in a bath of electrically non-conductive liquid with a very low boiling point, often around 50–60°C (122–140°F). Unlike single-phase systems, where the liquid simply absorbs heat and circulates to a heat exchanger, the magic of two-phase cooling begins when the components heat up the fluid to the point of boiling. The heat causes the liquid in immediate contact with these surfaces to vaporize. This liquid-to-gas transition absorbs a greater amount of thermal energy, far more than simple conduction, making it yet more efficient for extracting heat.

Once vaporized, the gas naturally rises inside the sealed tank until it meets a condenser, typically a cooled coil or plate located at the top. There, the vapor releases its stored heat to the chilled surface, condenses back into liquid form, and gently drips down like rain to the bottom of the tank, where it is ready to be vaporized again. This closed-loop system, boil, rise, condense, fall, is known as a thermosiphon loop, and it requires no mechanical pumping, making it incredibly energy-efficient and mechanically simple.

The efficiency of two-phase immersion cooling lies in the latent heat of vaporization, the energy required for a substance to change from liquid to gas at constant temperature. Dielectric fluids used in this system are specifically engineered to vaporize at lower temperatures so they can start removing heat quickly, right as components reach their optimal thermal envelope. Because of this, two-phase systems can maintain temperatures within a narrow, controlled band, often within just a few degrees, which is ideal for maximizing performance and stability in sensitive electronics.

In terms of practical application, this cooling method is especially well-suited for ultra-dense, high-performance computing environments, such as hyperscale data centers, AI model training clusters, or scientific simulation platforms that generate intense amounts of heat. Traditional cooling methods would require a tangle of fans, pipes, and chillers to reach the same level of heat extraction, and they’d do so at a much higher energy cost.

From an environmental standpoint, two-phase systems offer compelling advantages. By eliminating the need for complex mechanical cooling infrastructure, like CRAC units, chillers, and miles of ductwork, they drastically reduce the amount of electricity devoted to non-computational workloads. Many setups have achieved power usage effectiveness (PUE) ratings close to 1.02, which means almost all the power going into the system is used for computation, not for cooling.

The design, operation, and maintenance of two-phase immersion systems are more complex than their single-phase counterparts. Controlling the vapor space inside the tank, ensuring consistent condensation, and preventing fluid degradation over time requires specialized knowledge and deeper training. The initial setup costs are also higher, not just for the fluid and custom-engineered enclosures, but also for the supporting systems that must manage condensation efficiency and maintain an airtight environment to prevent fluid loss.

The choice of fluid is another crucial consideration. Since these systems rely heavily on precise boiling behavior, not all dielectric fluids will suffice. Fluorocarbon-based fluids, such as those developed by 3M (Novec) or engineered hydrofluoroethers (HFEs), are commonly used. While effective, these can be expensive and raise sustainability concerns depending on their global warming potential and end-of-life management. Fortunately, fluid manufacturers are increasingly aware of these issues and are beginning to develop lower-impact alternatives, though the market is still evolving.

Despite these challenges, the potential of two-phase immersion cooling is enormous. In edge environments where traditional air cooling isn’t feasible, or in dense computing racks that push thermal boundaries, this technology can offer a uniquely elegant and powerful solution. It’s not just about keeping chips cool, it’s about reimagining the entire philosophy of thermal design to align with the future of digital infrastructure.

Lifecycle and Sustainability of Dielectric Fluids

The lifecycle and sustainability of dielectric fluids, which are becoming specialized, electrically non-conductive liquids used in immersion cooling, are increasingly important as the tech industry seeks to align high-performance computing with environmental responsibility. These fluids are essential for managing heat in immersion-cooled systems, but their environmental impact spans from raw material extraction to end-of-life disposal or recycling. Understanding this full arc is key to evaluating their role in sustainable infrastructure.

Dielectric fluids originate from a few primary sources: synthetic hydrocarbons, fluorinated compounds, and natural esters derived from plant oils. Synthetic hydrocarbons, while thermally stable and long-lasting, are petroleum-based and energy-intensive to produce. Fluorinated fluids, often used in two-phase systems, offer excellent thermal properties but come with high global warming potential and environmental persistence. In contrast, natural esters, made from renewable crops like soy or rapeseed, are biodegradable, non-toxic, and often carbon-neutral over their lifecycle, making them a promising alternative for eco-conscious deployments.

Once sourced, these fluids undergo rigorous refinement to meet the demands of immersion cooling. This includes purification to remove conductive impurities, chemical stabilization to prevent oxidation, and the addition of performance-enhancing additives. The environmental footprint of this stage depends on the energy sources used and the efficiency of the manufacturing process. Some vendors are beginning to adopt greener practices, such as tighter closed-loop systems and renewable-powered facilities, to reduce emissions and waste.

During operation dielectric fluids can last five to ten years or more, depending on the system design and maintenance practices. Their longevity is a major sustainability advantage, as it reduces the frequency of replacement and the associated environmental costs. Proper filtration and monitoring can extend fluid life even further, and some systems now use sensors and AI to track fluid health in real time. This proactive approach minimizes waste and ensures optimal thermal performance throughout the fluid’s service life.

Eventually all dielectric fluids reach the end of their usable life, and how they are handled at this stage is critical. Fluorinated fluids are difficult to recycle and often require incineration under controlled conditions to prevent environmental harm. Synthetic hydrocarbons may be re-refined, though this is not always economically viable. Natural esters, however, are readily biodegradable and can sometimes be composted or used in bioenergy applications. Some manufacturers offer take-back programs or closed-loop recycling services, which help reduce waste and lower the total cost of ownership.

Beyond carbon emissions, sustainability also includes health and safety considerations. Fluorinated fluids can pose inhalation risks and are often classified as hazardous materials. Natural esters, by contrast, are generally safe for human contact and aquatic ecosystems. Many dielectric fluids are engineered to be non-flammable or have high flash points, reducing fire risk in data centers and improving overall safety.

Regulatory trends are also shaping the future of dielectric fluids. With increasing restrictions on high-Global Warming Potential substances and growing demand for transparency in supply chains, manufacturers are under pressure to develop low-impact alternatives. Innovations include bio-based synthetic blends, low-Global Warming Potential fluorinated fluids, and even water-based coolants. Life cycle assessments (LCAs) are becoming more common, helping operators make informed decisions based on environmental performance as well as technical specifications.

The long-term vision is to create a circular economy for dielectric fluids, where materials are reused, recycled, and responsibly sourced. This involves designing systems for easy fluid replacement, partnering with vendors who offer sustainable lifecycle services, and advocating for industry standards that prioritize environmental stewardship. In this model, dielectric fluids are not just passive materials but active contributors to a more sustainable digital infrastructure.

Environmental Impact

Immersion cooling is lauded for its energy efficiency and ability to support high-performance computing, but its environmental impact is more nuanced and deserves a closer, more holistic look. While it offers significant advantages over traditional air cooling, especially in terms of power consumption and thermal performance, the full environmental footprint of immersion cooling spans a complex lifecycle, from fluid production and system design to operational emissions and end-of-life considerations.

At the operational level, immersion cooling can dramatically reduce the energy required to maintain optimal temperatures in data centers. Traditional air-cooled systems rely heavily on fans, chillers, and HVAC infrastructure, which can consume 40% or more of a data center’s total electricity use. Immersion cooling eliminates the need for most of this equipment. The dielectric fluids used in these systems absorb heat directly from the hardware and transfer it efficiently to external heat exchangers, allowing for a wider range of operating temperatures and potentially reducing the need for the same mechanical refrigeration. This translates into lower power usage effectiveness (PUE), approaching 1.05 or better in some cases, meaning nearly all the energy consumed goes directly to computing rather than cooling.

This efficiency has a ripple effect. By reducing the energy needed for cooling, immersion systems also reduce the indirect emissions associated with electricity generation, especially in regions where the grid is still powered by fossil fuels. Because immersion cooling allows for denser server configurations, it can reduce the physical footprint of data centers, which in turn lowers the embodied carbon associated with construction materials like concrete and steel.

The environmental story doesn’t end with energy savings. The dielectric fluids themselves carry their own environmental burdens. Many of the most effective fluids, particularly those used in two-phase systems, are fluorinated compounds with high global warming potential (GWP). If these fluids leak or are improperly disposed of, they can contribute significantly to greenhouse gas emissions. Even in single-phase systems, where synthetic hydrocarbons or esters are more common, the production and refinement of these fluids can be energy-intensive and resource-heavy. Some are derived from petroleum, while others require complex chemical processing that may involve toxic intermediates or generate hazardous waste.

There is a growing push toward more sustainable fluid options. Bio-based esters and low-Global Warming Potential synthetic blends are emerging as viable alternatives, offering biodegradability and lower toxicity. A few vendors are also developing closed-loop recycling programs that allow used fluids to be filtered, reconditioned, and reused, reducing waste and the need for virgin material. These innovations are promising, but adoption is still uneven, and regulatory frameworks are only beginning to catch up.

Water use is another important dimension. While immersion cooling systems themselves are typically water-free, they often rely on secondary cooling loops, such as chilled water systems or evaporative cooling towers, to dissipate heat from the dielectric fluid. Depending on the design, this can either increase or decrease total water consumption compared to air-cooled systems. In arid regions or areas facing water scarcity, this trade-off becomes especially critical. Some newer systems are exploring dry cooling or heat reuse strategies, such as redirecting waste heat to nearby buildings or industrial processes, which can further enhance sustainability.

Material use and system design also play a role. Immersion tanks and enclosures must be built from corrosion-resistant materials, and servers often require modification to remove fans and adapt to submerged operation. While this can extend hardware lifespan by reducing thermal stress and mechanical wear, it also introduces new challenges in terms of recyclability and component compatibility. The long-term environmental impact of these specialized systems is still being studied, but early indications suggest that thoughtful design can mitigate many of the concerns.

Lifecycle assessments (LCAs) consider not just operational emissions, but also the upstream and downstream impacts of a technology, raw material extraction, manufacturing, transportation, maintenance, and disposal. Recent studies have begun to quantify these impacts across different cooling methods. Their findings suggest that while immersion cooling can reduce operational emissions and water use, the benefits depend heavily on fluid choice, system design, and regional energy mix.

Immersion cooling holds tremendous potential to reduce the environmental impact of data centers, particularly in terms of energy efficiency and thermal performance. But realizing that potential requires careful attention to the full lifecycle of the system, especially the sourcing, use, and disposal of dielectric fluids. As the industry matures, the most sustainable solutions will likely be those that combine high-performance cooling with low-impact materials, closed-loop fluid management, and integration into broader energy and water conservation strategies.

Regulatory Landscape and Market Trends

The regulatory landscape and market trends surrounding immersion cooling are evolving rapidly, shaped by the convergence of technological innovation, environmental urgency, and shifting policy frameworks. As data centers become increasingly central to global infrastructure, powering everything from artificial intelligence to cloud computing, the need for efficient, sustainable cooling solutions has never been more pressing. Immersion cooling, once a niche technology, is now at the forefront of this transformation. But its growth is not just a matter of engineering; it’s deeply intertwined with regulatory pressures, economic incentives, and broader market dynamics.

At the heart of the regulatory conversation is energy efficiency. Governments around the world are tightening standards for data center energy use, mostly driven by climate commitments and the sheer scale of digital infrastructure growth. In the European Union, the Energy Efficiency Directive and the EU Taxonomy for Sustainable Activities are pushing operators to adopt greener technologies. These frameworks don’t mandate immersion cooling specifically, but they create strong incentives for any solution that can reduce power usage effectiveness and carbon emissions. Immersion cooling, with its ability to slash cooling-related energy consumption by up to 50%, fits squarely within this policy-driven push for sustainability.

In the United States, regulatory momentum is building more gradually but is no less significant. States like California and New York are introducing stricter building codes and energy benchmarking requirements for large facilities, including data centers. The U.S. Department of Energy has also launched initiatives to improve data center efficiency, and while these are currently voluntary, they signal a shift toward more formalized standards. At the federal level, the administration’s climate agenda includes support for clean energy technologies and infrastructure modernization, which could indirectly benefit immersion cooling through grants, tax credits, or procurement preferences.

Asia-Pacific markets are also seeing regulatory shifts, particularly in countries like Japan, South Korea, and Singapore, where land and energy constraints are acute. Singapore, for instance, has imposed a moratorium on new data center construction unless operators can demonstrate exceptional energy and water efficiency. This has created a fertile ground for immersion cooling pilots, as companies seek to meet stringent environmental criteria while still expanding capacity. In China, the government’s dual carbon goals, peaking emissions by 2030 and achieving carbon neutrality by 2060, are prompting a reevaluation of data center cooling strategies, with immersion cooling gaining attention as a viable path forward.

Beyond energy efficiency, environmental regulations are beginning to address the materials used in cooling systems, particularly the dielectric fluids central to immersion cooling. Fluorinated fluids, common in two-phase systems, are under increasing scrutiny due to their high global warming potential and persistence in the environment. The European Union’s proposed revisions to the F-gas Regulation aim to phase down the use of hydrofluorocarbons (HFCs) and other potent greenhouse gases, which could significantly impact the availability and cost of certain immersion cooling fluids. In response, manufacturers are racing to develop low-Global Warming Potential alternatives and bio-based fluids that can meet both performance and regulatory requirements.

Market trends are closely tracking these regulatory developments. The global immersion cooling market, valued at around $286 million in 2024, is projected to grow at a compound annual growth rate of over 23% through 2030. This explosive growth is being driven by several converging forces. The rise of high-performance computing (HPC), artificial intelligence, and machine learning workloads is pushing traditional air cooling to its limits. These applications generate immense heat and require dense server configurations, making immersion cooling not just attractive but, in some cases, essential.

The economics of immersion cooling are becoming more favorable. While the upfront capital expenditure can be higher, due to the need for specialized tanks, modified servers, and fluid handling systems, the operational savings are substantial. Reduced energy consumption, lower maintenance costs, and extended hardware lifespan all contribute to a lower total cost of ownership (TCO) over time. As more case studies and pilot projects demonstrate these benefits, investor confidence is growing, and venture capital is flowing into startups focused on immersion cooling technologies.

The competitive landscape is maturing, as only a few years ago the market was dominated by a handful of pioneers. Today the field includes major players alongside a growing ecosystem of fluid manufacturers, system integrators, and service providers. This diversification is driving innovation and helping to standardize best practices, which in turn lowers barriers to adoption.

Standardization is a key piece of the puzzle. One of the challenges facing immersion cooling is the lack of universally accepted technical standards and certification protocols. Organizations like the Open Compute Project (OCP) and the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) are beginning to address this gap, developing guidelines for immersion-ready hardware, fluid compatibility, and safety protocols. These efforts are critical for scaling the technology, as they provide assurance to operators, regulators, and insurers that immersion systems can be deployed reliably and safely.

Another emerging trend is the integration of immersion cooling with broader sustainability strategies. Some data centers are exploring ways to reuse the waste heat generated by immersion systems, such as redirecting it to nearby buildings for space heating or using it in industrial processes. This kind of thermal integration not only improves overall energy efficiency but also aligns with circular economy principles and can help operators meet environmental, social, and governance (ESG) goals.

The market is also seeing increased interest in modular and edge computing applications. Immersion cooling is particularly well-suited to these environments, where space is limited and traditional HVAC systems are impractical. Compact, self-contained immersion units can be deployed in remote locations, harsh climates, or urban settings with minimal infrastructure. This flexibility is opening up new use cases in telecommunications, military, and disaster response scenarios, further expanding the market.

Among the biggest challenges are education and awareness. Many data center operators are still unfamiliar with immersion cooling or perceive it as risky or unproven. Overcoming this perception requires not just marketing but robust data, third-party validation, and industry collaboration. Demonstration projects, white papers, and peer-reviewed studies are essential tools for building trust and accelerating adoption.

Another challenge is supply chain readiness. As demand for immersion cooling grows, so does the need for reliable sources of dielectric fluids, immersion-ready hardware, and skilled technicians. Ensuring that supply chains can scale sustainably and ethically is a non-trivial task, especially given the geopolitical complexities of sourcing certain raw materials. Companies that can offer vertically integrated solutions or strong vendor partnerships will have a competitive edge.

Cybersecurity and data sovereignty are also entering the conversation. As immersion cooling enables denser, more distributed computing environments, questions arise about how to secure these systems and ensure compliance with data localization laws. While these issues are not unique to immersion cooling, they add another layer of complexity that operators must navigate.

Looking ahead, the regulatory landscape is likely to become more supportive of immersion cooling, albeit with tighter controls on fluid composition and environmental impact. Market trends suggest continued growth, driven by the twin imperatives of performance and sustainability. But the pace and shape of this growth will depend on how effectively the industry can address technical, logistical, and perceptual barriers.

In this context, collaboration is key. Industry consortia, academic researchers, policymakers, and end users all have a role to play in shaping the future of immersion cooling. By working together to develop standards, share data, and align incentives, stakeholders can accelerate the transition to more efficient, resilient, and environmentally responsible computing infrastructure.

The Future of Immersion Cooling

The future of immersion cooling is poised to redefine how we think about thermal management in computing, not just as a technical necessity, but as a strategic pillar of sustainable digital infrastructure. As data centers become the beating heart of everything from artificial intelligence to financial systems, the pressure to cool increasingly dense and power-hungry hardware is mounting. Immersion cooling, once a niche solution for experimental setups, is rapidly emerging as a mainstream technology with the potential to reshape the architecture, economics, and environmental footprint of computing at scale.

One of the most compelling drivers of immersion cooling’s future is the exponential growth of high-performance computing (HPC) and AI workloads. Training large language models, running real-time simulations, and processing massive datasets all require hardware that generates extraordinary amounts of heat. Traditional air cooling systems are already struggling to keep up, especially as rack densities climb beyond 30 kW and, in some cases, approach or exceed 100 kW. Immersion cooling offers a fundamentally different approach, submerging servers in thermally conductive, electrically insulating fluids that can absorb and dissipate heat far more efficiently than air. This allows for tighter hardware configurations, higher performance, and greater reliability, all while reducing the energy required for cooling by up to 95%.

Looking ahead, the market for immersion cooling is expected to grow at a blistering pace. Analysts project that the global market could reach over $2.5 billion by 2032, driven by demand from hyperscale data centers, edge computing deployments, and blockchain infrastructure. This growth isn’t just about performance, it’s also about sustainability. As governments and corporations commit to net-zero targets, immersion cooling offers a way to dramatically reduce power usage effectiveness (PUE) and water consumption, two of the most scrutinized metrics in data center sustainability. In fact, some immersion systems are already achieving PUE values as low as 1.02, a level of efficiency that would be nearly impossible with conventional air-based systems.

But the future of immersion cooling isn’t just about scaling up, it’s also about scaling out. Modular and edge data centers are becoming more common, especially in remote or resource-constrained environments where traditional cooling infrastructure is impractical. Immersion cooling’s compact footprint, low noise, and minimal maintenance requirements make it ideal for these scenarios. Imagine a ruggedized immersion-cooled micro data center deployed in a desert, a rainforest, or even aboard a ship, delivering high-performance computing with minimal environmental impact. This kind of flexibility opens up entirely new possibilities for how and where we deploy digital infrastructure.

Technological innovation will also play a critical role in shaping the future of immersion cooling. Advances in dielectric fluid chemistry are already yielding fluids that are more thermally efficient, less environmentally harmful, and more cost-effective. We’re seeing the emergence of bio-based and low-global warming potential fluids that align with evolving environmental regulations and corporate ESG goals. At the same time, hardware manufacturers are beginning to design servers specifically for immersion environments, eliminating unnecessary components like fans and optimizing layouts for fluid dynamics. This co-design approach, where cooling and computing are developed in tandem, will be essential for unlocking the full potential of immersion systems.

Standardization and interoperability will be another key frontier. As more vendors enter the space, there’s a growing need for common protocols, safety guidelines, and performance benchmarks. Organizations like the Open Compute Project and ASHRAE are beginning to address this, but much work remains. The development of industry-wide standards will not only reduce risk and complexity for adopters but also accelerate innovation by enabling plug-and-play compatibility across systems and components.

From a business perspective, immersion cooling is also beginning to shift from a capital-intensive experiment to a financially compelling investment. While the upfront costs can be higher than traditional systems, the long-term savings in energy, maintenance, and hardware replacement are substantial. As more case studies and pilot projects demonstrate positive ROI, we can expect to see broader adoption across industries, not just in tech giants and research institutions, but also in sectors like finance, healthcare, and manufacturing, where data-intensive applications are becoming the norm.

Perhaps most exciting is the potential for immersion cooling to serve as a catalyst for reimagining the entire data center ecosystem. By enabling higher densities and more efficient thermal management, immersion cooling could lead to smaller, more distributed data centers that are closer to end users, reducing latency and improving resilience. It could also facilitate new forms of heat reuse, such as district heating or industrial process integration, turning data centers from energy sinks into energy hubs. In this way, immersion cooling isn’t just a better way to cool servers, it’s a building block for a more sustainable, decentralized, and intelligent digital future.

There are challenges still to be solved, such as fluid sustainability, supply chain readiness, workforce training, and regulatory clarity are all areas that need continued attention. But the momentum is undeniable. As the digital world grows more complex and interconnected, immersion cooling offers a rare convergence of performance, efficiency, and environmental stewardship. It is not just a solution to today’s problems; it’s a foundation for tomorrow’s possibilities.

Sources:

Open Compute Project – Immersion Cooling Project

Wikipedia – Immersion Cooling

Upsite Technologies – “Immersion Cooling: The Good, the Bad, and the Ugly”

Vertiv – Advancing Data Center Performance with Immersion Cooling

Park Place Technologies – What Is Immersion Cooling for Data Centers?

Eabel – Immersion Cooling for Data Centers: A Comprehensive Guide